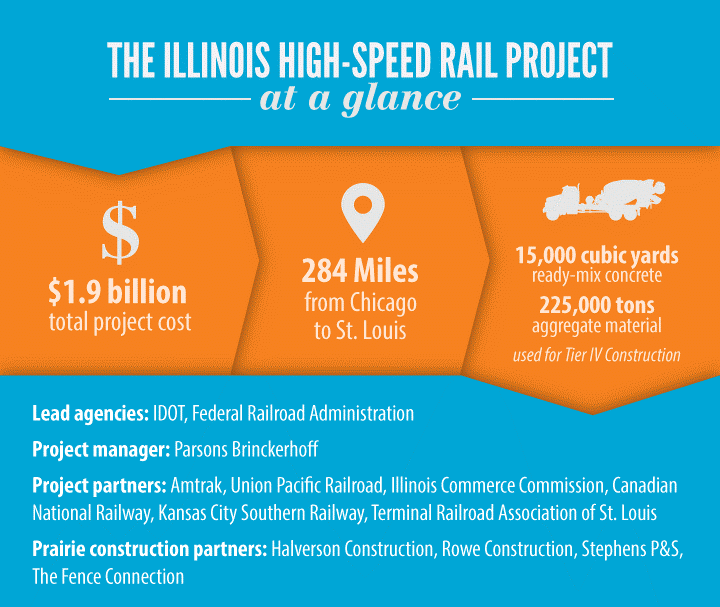

Prairie supplies top contractors who are moving the $1.9-billion project forward

Working with nearly $1.3 billion in federal funds, a partnership that includes IDOT, the Federal Railroad Administration, Amtrak and the Union Pacific Railroad (UP) needed contractors with suppliers they could trust to transform the 284-mile rail route from Chicago to St. Louis into a high-speed corridor that will reduce travel times by a full hour by 2017.

Since the project launched in 2010, the UP — which owns the right of way south of Joliet and operates freight service through the corridor — has refurbished 262 miles of track, building second rails and sidings that will allow Amtrak Lincoln Service and Texas Eagle trains to move past freight traffic at speeds up to 110 mph.

In 2015, Prairie’s Pontiac Aggregates Yard supplied more than 45,000 tons of RR-1 and 130,000 tons of CM0-6 aggregate for Halverson Construction of Springfield. Halverson crews are working on three new sidings in the Tier IV project zone between Chenoa and Lincoln, Illinois.

The RR-1 stone, sized from one to three inches, is being placed at depths of one to four feet as needed to remediate poor soil conditions in the track bed. This form of aggregate is especially effective at filling deeper holes and offers excellent interlocking characteristics, providing greater stability and resistance to extreme compression cycles from high-speed rail traffic.

The CM06 stone serves as the compacted base for the rails and adjacent access road, placed at depths of 12 to 20 inches, depending on grade. It provides a smoother top to seal surfaces, prevent vegetation growth, aid in drainage and resist the long-term effects of runoff and freeze-thaw cycles.

“We started the 2015 season with no stockpiles on the ground, so we needed extra capacity to meet project requirements,” says Pontiac Operations Manager Chris Basham. “We added two new team members, and the entire crew has worked 12-hour shifts, 5 days per week, and an 8-hour day on Saturdays. For the first three to four months, we ran a Caterpillar D10 bulldozer 24 hours a day and increased our blasting schedule to keep up with demand.”

Concrete for crossings, fencing and sound walls

Track construction is just one aspect of this massive, multi-year project, and Prairie Material’s ready-mix operations in Central Illinois are providing more than 15,000 cubic yards for job sites in the Tier IV corridor.

“To date, we’ve delivered about 3,800 yards for Halverson Construction, including 600 yards of integrally colored mix for barrier walls near cities and towns,” says John Drew, Prairie operations and sales manager in Bloomington-Normal.

“To date, we’ve delivered about 3,800 yards for Halverson Construction, including 600 yards of integrally colored mix for barrier walls near cities and towns,” says John Drew, Prairie operations and sales manager in Bloomington-Normal.

The 8-foot walls, tinted a light brown with pigments furnished by Solomon Colors, serve as an attractive sound barrier for nearby homes and businesses, Drew says.

Prairie is also the ready-mix supplier for Rowe Construction of Bloomington, whose crews are rebuilding all grade-level crossings in the 55-mile Tier IV zone. Two more contractors – Stephens P&S and The Fence Connection — will use 5,000 yards of Prairie concrete to install steel fencing and lay foundations for precast barrier walls near population centers.

A new vision of intercity travel

Advocates say the new high-speed route will change the way we travel in the Midwest. When the full corridor opens in 2017, travel times between Chicago and St. Louis will shrink to 4½ hours — an appealing choice for those tired of airport delays and heavy traffic around major cities. The route’s success may soon mirror Amtrak’s New York-to-Washington D.C. corridor, where three times as many passengers chose trains over airplanes in 2014.

READ MORE

- November 2015 project update in Progressive Railroading

- IDOT project website

United Materials

United Materials Superior Materials

Superior Materials Prairie Materials

Prairie Materials Canada Building Materials

Canada Building Materials VC Global

VC Global